Did you know that a common print and dye technique could be a key indicator that your clothing was sewn in less than ethical and sustainable conditions? And, it might even be putting your health at risk. If you didn't, then you need to be on the lookout for pigment pints, pigments, dyes, and their tell-tale sign of color crocking.

what is pigment ink?

First, let's define pigments. A pigment is something that gives color.

There are two main types of inks in textile printing. The first is dye. With a dye ink, the color basically absorbs through a chemical reaction into the fibers.

The second type of ink is pigment. With pigment ink, the color sits on top of the fabric and is usually held in place by a chemical resin or binder. Resins and binding agents are basically glue. And, the pigments in pigment dyes tend to have a larger molecule size than the dyes mention above.

Pigments prints are recognizable because they have a stiffer handfeel than dye prints due to the resin binder. As a general rule darker and more saturated pigment colors tend to be stiffer than lighter colors.

what is a pigment print?

Pigment prints are made using, you guessed it, pigment based inks. And, they are one of the cheapest and most common types of prints in the textile market.

Pigments prints are a type of direct print. A direct print, aka application print, is a category of print where the design prints directly onto the fabric. We will get more into different types of prints in our Textiles 101 Textile printing post coming soon.

you have probably pigment printed before…

If you went to camp, you are probably familiar with screen printing, a popular camp activity. This is an example of pigment printing! Pigment ink presses by hand through a pattern on a screen, and deposits color onto the surface of shirts, tote, bags, or anything else under the screen.

And, while we are on the topic of camp crafts, check out this post about dyes that talks about another camp classic tie dye.

technology upgrades...

But, screen printing is becoming a vintage printing technique. Today there are at home digital pigment ink printers that print on fabrics.

They work the same way as an at home printer. Upload an image from a digital file, and press print. It's that easy. There is no need to make time-consuming screens.

Every so often I get a few people reaching out to me who want to start screen print companies. While the idea is novel, handmade in someone's garage, the problem is it's time-consuming. And here in the United States labor is expensive (hopefully). So to them, I always recommend thinking about investing in a pigment printer - here is one by Epson.

The other benefit to these modern machines is you can print a full color gamut, not just the basic 1 color or 2 color logos we tend to view on traditional hand screens.

Didn't go to camp and get to experience hand screen printing? That's ok. I still bet you have done pigment printing.

I can almost guarantee it 100%. That is because there are other types of pigment printing than just textiles. Pigment inks are everywhere.

Have you ever printed papers on an inkjet printer? Well, then you are a pigment print pro! Inkjest printers are a form of pigment printing, just on paper.

But, don't get carried away, at home inkjet prints are not the same as the epson textile pigment prints. Warning for anyone getting ideas… You can not print a shirt in your at home printer. The machines are totally different, and the pigments are different formulas, you will ruin your office printer if you try to print textiles on it.

print or dye?

When you are looking at a piece of fabric there might be a lot of colors, so it is difficult to tell how it was made. Let's take the example of a leopard print. The print has three colors, tan, brown, and black. There are a couple of ways of producing this.

The first would be to take a white piece of fabric and print each color on. This would be the cheapest way of manufacturing. (***keep this info in mind for later.)

The other would be to first dye the fabric tan and then only print the black and brown portions. This would allow the tan parts of the fabric to be softer (remember I told you about how pigment prints are much stiffer than dyes?).

But, if you are unfamiliar with prints and how they are made - how can you tell the difference?

pro tip...

A quick way to tell a print from a dyed fabric is too look at the back. When a fabric is dyed the color will be on the face and back when the same fabric is printed only the color will appear on the front. It's that easy.

pigment dyeing

what is a pigment dye?

Pigment dye is pretty similar to pigment ink in printing. Except the color is applies to the entire piece of fabric not just a small section in a print. Maybe you are thinking, why on earth would anyone want to cover an entire piece of fabric in stiff pigment dyes. Well, there are a couple of reasons.

benefits to pigment dye

$$$

If pigment prints are stiff, then why does fashion use them? To be blunt, they are cheap, and, as we all know, fashion is all about saving money and increasing the bottom line.

Easy application

Because pigment dyes sit on the top of fibers and fabrics instead of absorbing like direct or acid dyes this means the amount of chemistry needed is almost totally eliminated.

For example, acid dyes are for dying fibers like nylon, while direct dyes only react with natural fibers like cotton. If you try to dye nylon with a direct dye it will be a mess. The fact that different dyes are needed for different fibers is extremely problematic when it comes to blended fabrics.

Let's pretend we have a nylon/cotton blend shirt that needs to be dyed. If we dye it with only direct dyes the nylon will remain white and give the shirt a marble effect. So we need to dye the fabric again with an acid dye. Dying a fabric twice, with two different dyes, to achieve one uniform color is cross-dying.

But, it can be hard to exactly match the same exact red on both fibers. And the process of double dying weakens the fibers, making the entire fabric weaker.

Basically, the entire process is very time consuming, and there can be a lot of wastage from trial and error trying to get the dye formulas just right.

That's where pigments come in. Because they sit on top of the fiber and don't react with it they can be applied to almost any fiber and the color will look uniform.

color matching

Speaking of saving time, pigment dye is the easiest to match. By using pigment dye there is a reduction in fabric wastage because the fabric will match from lot to lot.

neons on natural fibers

It seems like the trend of bold, bright, floro, and neon colors are not going away anytime soon. Chalk it up to festival culture I guess. But, people are more and more demanding natural fibers in their clothes over polyesters and rayon. The problem with the trend of bright colors and natural fabrics is that the two don't play well together. Using direct or reactive dyes it is impossible to achieve most ultra-bright colors.

But, with pigments, that sit on top of the cotton and just coat it, the bright colors festival goers crave is possible.

And, most people who are buying festival clothes want them cheap. They want to wear them once, take their instagram shots, and toss them. Another additional bonus of pigment prints, keeping costs and prices down.

And, the last benefit to pigment dyes is that they tend to have good colorfastness. This means that they will not lose their color over time from the sun or other natural elements.

less water usage

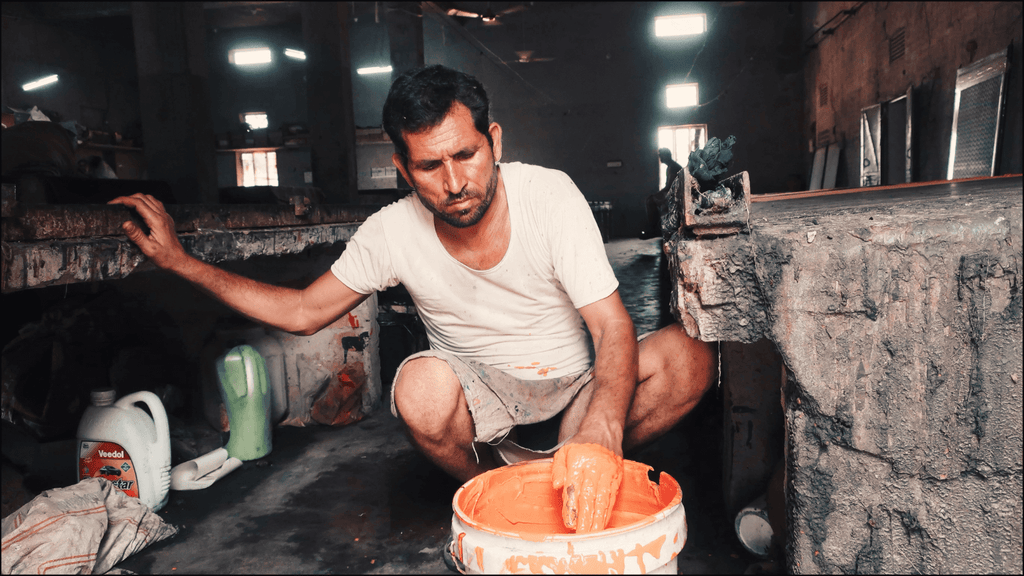

Pigment dyes do not require the massive amount of water that dye does. Pigment dye does not require water, because, pigments are insoluble (they can not dissolve in water, they just float around in it). Instead, pigment dyes must be pressed into the fabric as a paste, not a solution.

negatives to pigment dye

There are some positives to using pigments instead of dyes. But, pigment dyes and inks are far from perfect. They have some serious performance issues.

require a lot of heat

While pigment dye saves on water use, they still require a lot of heat. After the dye is pressed into the fabric it mused be heated. This is the process of curing where temperatures can reach up to 400 degrees Fahrenheit.

perform poorly in the laundry

Every time a pigment print is washed, a little bit of color comes off. Generally, after about 20 wash cycles a garment will start to show a decrease in color vibrancy. Clothing utilizing pigment dye will not last forever, it's fast fashion.

stiffness

I mentioned fabric stiffness a few times before. But I will mention it again.

dye crocking

Because pigment dyes sit on top of the fabric they have a tendency to crock. Crocking is when color rubs off onto something else. Generally, dark colors and reds tend to have the most crocking problems.

Crocking can be an issue when you have a white shirt with a black print. If the black crocks, or transfers onto the white the shirt will have black stains. The process is also known as dry crocking because it happens when the fabric is dry.

but, in some cases, crocking can be good

Did you know that indigo is a pigment dye? When dye houses dye indigo yarns, a coat of indigo pigments wraps around the outside of the yarn. Indigo dying is kind of like candle dipping (another camp activity). The yarns dip between 3-9 times, each time a new layer of indigo wraps around the yarn, and with each dip, the color becomes darker.

And, this special dye and process is what gives indigo all of its character. As the layers of blue wear down (whether this is done artificially in the factory with hand sanding or in real life), designs like whiskers and shade variances at the knees start to appear.

The process of crocking or color loss is especially obvious in raw denim. Raw denim starts out almost black and slowly fades into a pair of custom jeans after crocking occurs. You can tell the points of the garment that have high abrasion (or a lot of mechanical action / rubbing) because they are the ones that wear down first. The cool thing about raw denim is that your pair is totally unique to how your body moves, and how the indigo is rubbed off.

cracking

If the pigments are too heavy they create almost a coating that can crack when the fabric stretches.

fast fashion exposed - why pigment prints are a clue to poorly made product

If your clothing was made using pigment prints it could be a clue they are poor quality or made in less then ideal working conditions.

Here's why.

lower quality fabrics

Remember how I mentioned (a lot of times) how pigment prints and dyes make a fabric more rigid and stiff. There is no point investing in nice fabrics if stiff pigments will cover them up. For that reason, pigment dye fabrics are generally the lowest and cheapest quality fabrics around. The fibers have short staple length, the yarns have inconsistent sizing, and even sometimes, the fabric has slight damage. But, that's all ok because the pigments are going to just cover all that up.

mass production

Pigments cover everything. A lot of times in fashion if we know that something is going to sell well we will make more of it.

Let's go back to the t-shirt example, we know every year they are a best seller. But, what changes from year to year is the color that sells the best. In order to still get the financial perks of making in mass quantities, but not have to commit to colors, the industry uses garment dyeing.

Garment dying allows factories to dye an entire garment at once. The problem is that during the dyeing process the dyes used might not react with the sewing threads or other components of the shirt, leaving them a different color. With pigment dyes, the entire garment coat of pigments in the same color, and everything will match perfectly.

lack of transparency

Unlike other types of dyes that are temperamental and only get along with certain types of fibers, pigments work for everything.

This means that dye houses do not need to know what they are dying, or do any sort of fabric testing. They are able to simply coat whatever fabric comes through their door in the pigments.

Again, testing fabrics for content, and creating custom dye formulas is time-consuming and expensive. In fast fashion time is key. And the faster something can get done the more money a company can make. Pigments are a sure sign that speed of production was the highest priority.

And, pigments can be dangerous

Have you heard of phthalates?

I feel like no one is talking about them in the sustainable fashion world… there are a few bloggers that have been ripping off my work, so I am really curious to see if they start talking about them now. I hope they do, everyone should be talking about them, but it would be nice to get a little mention sometimes ;)

So pigment prints and pigment dyes are super stiff. To soften them textile chemists came up with a solution. Add phthalates. The phthalates work to soften the effects of the pigments and create a softer fabric. Sounds great? Well, not really.

Phthalates have links to the liver, kidneys, lungs, and reproductive system damage. There is no denying they are dangerous because they are banned from all children's clothing. Kids clothes have the highest safety regulations. And, the American Association of Textile Colorists and Chemists has a strict set guide on how to test for and detect phthalate. There are inks made without phthalates but they are rare and tend to be more expensive.

If phthalates are concerning to you now, watch out for them in your shoes, or any types of rubbers and plastics you buy… I am thinking I should do a post soon about hidden toxins in textiles…

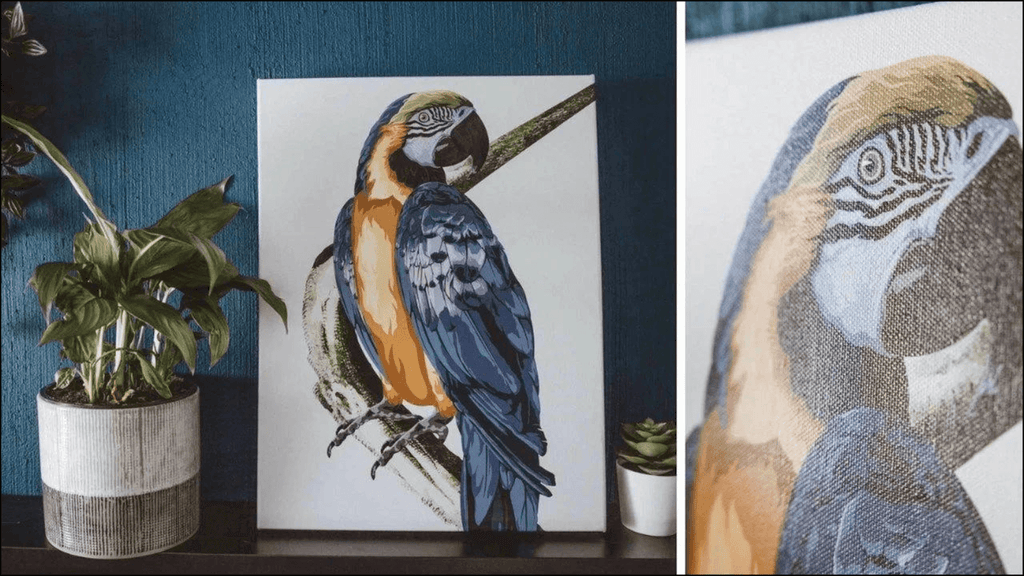

Other pigment prints

This isn't textile related, but I thought it was pretty cool. Art prints are now being made with pigment inks. I love when things that I know about from the world of textiles and fashion, are actually in other industries as well.

In the Fine art community, archival pigment prints reproduced using pigments. The technical term for the process is giclee. And its basically a really high-quality digital pigment print. Today some works of art in museums and gallerys aren't even the real thing, they are artist prints made as replicas, so the real paintings can be cared for and protected.