The first topic of Textiles 101 WHAT ARE TEXTILE FIBERS? And, why are they important in sustainable fashion design? Get ready to learn everything there is to know about the very first step in designing a product.

Textile Fibers - the first step in the product supply chain

The first step in choosing, or developing a fabric is considering what type of fibers to use. To do this, we need to understand what fibers are, where they come from, and what makes them different from each other. We know a cotton shirt feels and performs very differently than one made out of polyester, but why? Choosing the right fibers can be the difference between a top selling product and one that sits on the shelves.

BUT BEFORE WE GET STARTED...

I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business.

They won’t be free forever, so make sure to grab them while you can.

- CUT YOUR SOURCING TIME IN ½ - the industry sourcing doc you didn’t know existed but definitely need

- HOW MUCH DOES IT REALLY COST TO START YOUR BRAND – I have helped people with as little as $2,500 get started; here’s how…

- NO MORE EXCUSES – get the exact productivity system I use to get things done

What are textiles?

Textiles are materials or fabrics. They are made of tiny fibers that can be man-made or come from nature, those fibers are then twisted into yarns, and the yarns are then woven or knit into a fabric.

When designing a high-quality fabric the first, and most arguably most important step, is fiber selection. You can try your hardest, but if you start out with bad fibers, you will never be able to create a superior textile.

We measure textiles by weight. Thre are two systems of measure - GSM and OZ/SQ YD. GSM, grams per square meter, measures how many grams a 1 meter by 1 meter square of fabric will weigh. OZ/SQ YD, ounces per square yd, measures how many ounces a 1 yard by 1 yard square of fabric will weigh.

Sometimes these units of measure can get confusing. And depending on the countries you work in you might need to convert them. But, don't worry that is easy. Use, our handy calculator!

So. What is a fiber?

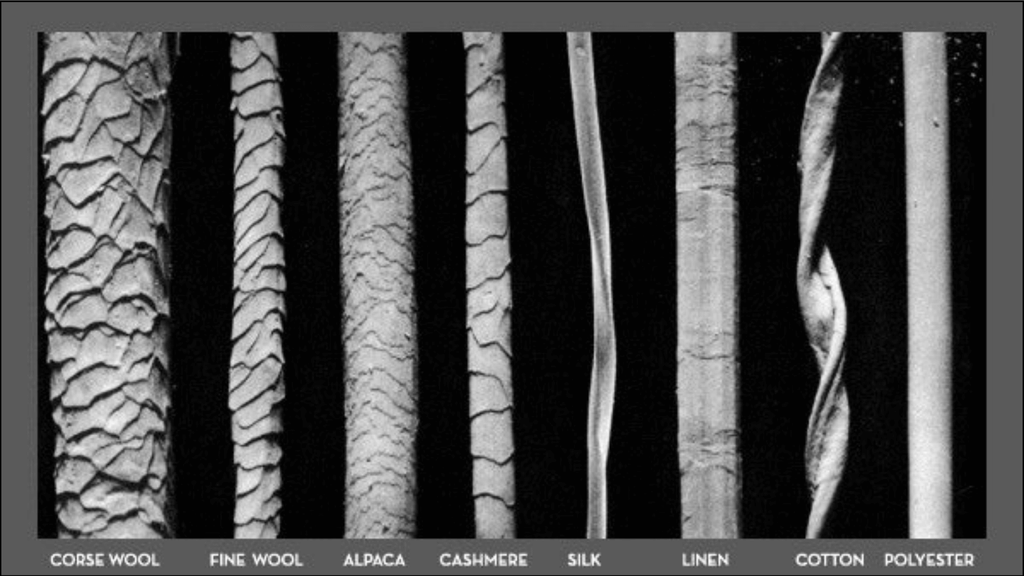

Now that we know what are textiles, we can dive into fibers. A fiber is a very thin, hair-like structure. Actually, your hair is technically a fiber. Fibers are so tiny that we measure them in microns. A micron is equal to one, one-thousandth of a millimeter (1/1,000). They are generally much, much, longer then they are wide. The differences in the fibers chemical composition and, molecular and physical structure, give a fiber its performance characteristics.

Fibers are usually twisted together to form yarns, and yarns are then woven or knit to form fabrics… But, we are getting ahead of ourselves.

What are different types of fibers in textiles?

Knowing the type of fiber you will use is not only important for product development and creating the best product possible, but also for your import and export duties. Some textile fibers, like cotton, actually receive lower import taxes than a synthetic fiber like polyester. If you know the rules, and how to optimize fiber blends, you can create a premium product and save your company some serious cash.

Natural vs. Manufactured

There are two main classifications of textile fibers, they are natural and manufactured, or synthetic. They are exactly what they sound like. Natural textile fibers derive in nature, like from plants and animals. Synthetic textile fibers which require manufacturing in a laboratory. Synthetic fibers help fill in the gaps or solve specific needs that natural fibers can not. In other words, their design is for specific performance.

There is no such thing as a perfect fiber. Every fiber has its pros and cons. The art of textile science is to blend fibers, yarns, and weaving or knitting techniques to create the fabric that is perfect for what you are specifically designing.

Filament vs. Staple

Did you know that textile fibers can range from less than 1 inch to miles in length? What is a staple fiber? Staple textile fibers are shorter fibers that are measured in inches. Filament textile fibers are much longer and need larger units of measure to record their length.

As a general rule, all natural fibers are staple length. To give you an idea of their size, here are a few natural fiber lengths: cotton = ½” - 2 ½”, flax = 2” - 26”, and wool is about 1” - 18” long.

But, there are a few exceptions to this rule. They are silk, metal, and rubber.

Silk, when unrolled from an unbroken silkworm cocoon, is 1 continuous filament yarn that measures about 4800 feet long.

It is possible to create filament fibers of metal and rubber by manufacturing them to form 1 long continuous filament fiber, even though this form is not the organic form they take in nature.

Synthetic fibers are all filament fibers originally. A fiber like spandex is always a 1 long filament. But, a synthetic fiber like acrylic can be cut up into staple length fibers before twisting into yarn. By cutting up a synthetic fiber into staple length size, the yarn and final fabric will take on characteristics much closer to those of a natural fiber. Acrylic fibers in an acrylic sweater are cut to about the same staple length as wool fibers, and that is way acrylic sweaters often feel interchangeable with real wool.

What are different Types of Natural fibers?

Plants vs. Animals

Natural fibers are split into two main groups - plants and animals. Plants are cellulosic based (made of cellulose), like cotton and hemp. And, animal fibers are protein based, like wool. Knowing this will help alot when we start to talk about different dye types later on in another mini-course.

Types of Plant Fibers

What are types of plant fibers? The plant fiber group is then broken into 3 subgroups. These are fibers that come from the stem of the plant like flax, hemp and jute, fibers that come from the leaves of plants like sisal and abaca, and lastly, fibers that come from the seed portion of the plant like cotton and kapok (kapok is cotton's wild cousin).

Animals fibers just come from animals, some examples include yak, alpaca, sheep's wool, and vicuna.

What about silk?

Silk comes from the cocoon of the silkworm. We consider it to be an animal-based fiber. Traditionally the cocoons were thrown into chemicals or boiling water to unravel the silk filament, killing the worm in the process. Today, many people find this practice cruel, so there is peace silk. This type of silk allows the worm to hatch from the cocoon, and then the fibers are gathered. The problem with this is that the silk yarn is not 1 long continuous fiber, so peace silk is not as smooth and consistent as traditional silk manufacturing methods.

Synthetic fibers

Synthetic fibers are man-made in a lab. Each fiber is made through a process called extrusion. Generally, synthetic fibers belong in three groups cellulosic, protein, and petroleum-derived.

To make a synthetic fiber, a solution is pushed through a device called a spinneret. A spinnerette resembles a shower head or spaghetti strainer. It is a small device ranging from less than an inch to almost a foot in diameter with holes in it. The holes can be made in all different shapes and sizes, and each spinneret can have anywhere from 10 to 10,000 holes in it. The shape of the holes, their size, and how many of them there are will ultimately affect the properties of the yarns they create.

3 ways to make a synthetic fiber

There are 3 different methods of creating a synthetic fiber, they are dry, wet, and melt.

Wet is generally the most popular method, and is how we make rayon. In wet spinning, fiber chemicals extrude into a liquid chemical bath. When the fibers meet the chemical bath it causes a chemical reaction that hardens the liquid into a solid fiber.

In dry spinning, the fiber chemicals extrude into the air, and the air will then trigger a chemical reaction and quickly dry the solution, forming them into fibers.

Lastly, melt spinning uses heat to melt a solid chemical and then extrudes the melted liquid through the spinneret into cooler air. The cold air helps to cool the fiber back into its original solid state.

How can you tell what fiber is what?

Telling fibers apart can be tricky at first. Remember, many synthetics are made to mimic natural fibers. And, often, different types of textile fibers are blended together. I remember when I was in college at FIT, when I went shopping I would test myself by trying to guess the content of each garment. When I first started this game I got it wrong almost all the time. But, now after years of practice, I’m at 99% accuracy, hey, no one is perfect.

If you are dealing with a mill and worried they might be lying to you and trying to sell you a cheaper fabric… I can not tell you how many times people thought they were buying expensive silk and were really buying rayon blends, you can use this trick. It’s the burn test.

The burn test

The burn test is just what it sounds like, take that fabric and burn it.

First, separate out a few fibers, then set them on fire. The way the fabric burns, and smells will tell you a lot about where it came from.

Plant-based textile fibers when burned will smell like burning leaves in the fall, and the fibers will turn to ash like what you find in a campfire.

Rayon, Tencel, and Lyocell are tricky. Because they are plant-based cellulosic synthetic fibers. When we burn them, they will burn like cotton and smell like burning leaves. So, we need more information to differentiate them. As a second test, you can look at fiber length. Synthetic textile fibers are generally very, very long, sometimes they are the full length of the fabric. Natural plant based fibers tend to be short, only an inch or two at most in length. If the synthetic fibers were cut into staple length then you will need to rely on a lab to do chemical testing.

Animal fibers, including silk, will smell like burning hair.

Petroleum-based synthetic fibers, like polyester, will melt when burned, and turn into hard balls of plastic.

Fiber Glossary

Before we dive into basically every single type of fiber and the pros and cons of using them, here a few textile jargon terms that will make talking about textile fibers a little easier.

Common fiber in textile terms explained

Abrasion Resistance

Abrasion resistance is the ability for a fiber to withstand wear and tear from rubbing. Nylon is one of the strongest textile fibers available. And because of this, it is often a component in performance and athletic wear clothing because of its ability to withstand abrasion caused by movement.

The most infamous public example of abrasion resistance is from Lululemon. In 2013 Lululemon’s founder Chip Wilson stated “Frankly, some women's bodies just don't actually work [for the yoga pants...It's more really about the rubbing through the thighs, how much pressure is there over a period of time, how much they use it."

Technically the science behind his statement is true according to the academic definition of textile abrasion resistance. But, the comments definitely could have been made a bit more tactfully.

Instead of blaming women for not having thigh gaps, Lululemon could have replaced their cheap polyester styles with stronger and more expensive nylon alternatives to create a better, and longer lasting product that didn’t put the blame on women's bodies.

Absorbency

Absorbance is how well a fiber can take in moisture. Absorbancy measures the amount of moisture a completely bone dry fabric can take in under the standard testing conditions of 70 degrees Fahrenheit and 65% humidity in the air.

Absorbency effects…

Skin Feel

High absorption is good for keeping the skin cool in hot and wet conditions (like working out).

Electric Shocks and Mold

Low absorption leads to fibers and fabrics with high static build-up. And, did you know that high static build-up actually attracts dirt and makes clothes appear dingy faster. But, too much absorbency can create the optimal environment for molds and mildews to grow.

Stretch

Fibers and fabrics with high absorbency tend to stretch out a lot when they become wet. This is why we do not make swimwear out of cotton.

Stain Removal

Fibers and fabrics that have high absorbency are easier to clean because it is easier for soap and water to get in and do their jobs. That is part of the reason why polyester workout clothes start to stink, soap and water don’t work as well when they can absorb into the fiber.

Wrinkle Recovery

Wrinkles in clothing after laundering are partially from high moisture absorbency. What happens is that during the laundering process the fibers take in a lot of water and swell up. Then when the clothes dry the fibers shrink back down creating wrinkles in the fabric. For this reason, fabrics made out of textile fibers like polyester, which does not absorb water well, (you can wash and dry, and never have wrinkles) are wash and wear, and easy care.

Cover

Cover is another term for bulk. Textile fibers with good cover have a lot of crimp. They take up a lot of space for their weight. Again, wool is an example of a fiber with good cover.

Crimp

Crimp is exactly like what you think of when your picture 80’s crimped hair. It is the bends, twists, and kinks along a fiber. Fibers with more crimp tend to be warmer, have increased absorbency, and feel nice and cozy on the skin. Crimp is natural in animal fibers like wool and is also possible to engineer into synthetics. Engineering crimp requires the process of heat setting. Crimp, can also be added to the yarn by texturing.

Elasticity

There are actually two parts to elasticity. The first is stretch or elongation. This measures how far we can pull and lengthen a fiber. The second part is recovery. This is how close can the fiber return to its original length after stretching.

Stretch is key for comfort, especially in form-fitting clothes. It is what allows us to move freely. It also helps to add to the longevity of a garment by reducing the tension placed on seams, helping them to not split and last longer. And, as an added bonus it also increases the strength of fabrics.

There is a special category of elastic textile fibers, they are elastomeric fibers. Spandex and rubber belong to this group. Elastomeric is basically just a fancy word that means a fiber can stretch over 100% its original length.

Flammability

Flammability measure how quickly a fiber or fabric can catch fire. Textile fibers belong in three groups, flammable, flame resistant, and flameproof.

It is common for fibers and fabrics to receive chemicals treatments in order to achieve flame resistance and flameproof testing requirements.

Did you know that in the USA children's pajamas must pass rigorous flammability testing?

Flexibility

How easily can a fiber bend? Glass is an example of a fiber with low flexibility, it is extremely rigid. Yes, glass is a fiber. Silk is an example of a fiber with high flexibility. Fabrics that use flexible fibers have good drapability.

Hand

Hand describes how a fabric feels. It is highly subjective. Is it smooth, scratchy, stiff, cool, crisp, dry, warm, fuzzy, etc?

Hydrophilic

Hydrophilic means that a fiber loves water and can absorb a lot of it. And, an example of a hydrophilic fiber is cotton.

Hydrophobic

Hydrophobic means that a fiber does not like water. These textile fibers also tend to oleophilic. This means that they like oil, and will absorb oil. An example of a hydrophobic fiber is polyester.

Luster

Luster describes how light reflects from the surface of a fiber. Fibers with high luster are very shiny. High luster fibers tend to be very smooth and round like many synthetics. Fibers like wool, that have crimp or are scaly or irregular shapes, will have lower luster and appear dull. The types of twist in yarns and the type of weaves and knits can also effect luster.

Pilling

Pills are the little balls of fuzz that build up on your clothing. Pilling happens because of tiny broken fibers.

Hydrophobic fibers (textile fibers that repel water) tend to pill more than hydrophilic (textile fibers that like water) fibers. This is because hydrophobic fibers they have more static build-up, and end up clinging together on the surface of the fabric instead of falling off.

Wool is an exception to the rule. Wool, although hydrophilic, tends to pill because the surface of the wool fibers is scaly and the scales stick to each other and to the fabric.

Resiliency

Resilience is closely related to wrinkle recovery. How well can a fiber or fabric return back to normal after crumpling it up? Thicker fibers and round shaped fibers tend to have better resiliency

Static Electricity

Static electricity is an electric charge made from friction (rubbing). I am sure you have all heard of the dreaded wintertime static cling. The one where a pair of underwear is stuck inside your clothes only to fall out at the most inopportune time in front of your co-workers. Static cling is especially common during the winter because the winter months tend to be much drier, and electric charges do well in dry environments.

There are special epitropic fibers that are made to resist static build-up. These types of textile fibers are crucial to certain jobs where static shocks could be dangerous like hospitals, computers, and near highly flammable chemicals.

Strength

Strength is just what it sounds like. How much force will break a fiber or fabric? Nylon is one of the strongest commodity fibers available, while acetate is extremely weak. Acetate is very cheap and often used as a cost-saving alternative to line the inside of jackets. This is why in some fast fashion jackets the line starts to fray and rip from just a little bit of wear.

Thermoplastic

Thermoplasticity describes how well a fiber can withstand exposure to heat. This is extremely important when we print, dye, and finish fabrics, because during these processes a lot of heat is necessary.

A thermoplastic fiber will become soft from heat exposure. This allows for finishes such as heat setting, permanent press, and anti-wrinkle. In theory, the fiber is melted into place in permanent press garments.

Wicking

Wicking, the performance, and athletic apparel industries favorite buzzword. But, what is it really? Wicking is simply, how well a fiber can transfer moisture.

During wicking, moisture moves from your body through the fabric to the surface of the fabric. The moisture then evaporates into the air. Effectively, wicking is just how well a fiber or fabric can move moisture.

Guide to every type of fiber ever

Ok here is the part you have been waiting for. What textile fibers to use when.

Sign up for our newsletter to get updates on the release of the next virtue + vice Textiles 101 topic, Natural Plant Fibers.

Fibers in Fashion will cover the pros and cons of virtually every plant fiber out there, and when to use what fiber for the highest performing clothes possible!

1 comment

Very informative. Very well summarized . I found it helpful as I have be out of the field in a couple years and needed revision in order to get back upto dated.

Leave a comment