At virtue + vice I strive to help my clients use different production methods that have the lowest environmental impact possible. One method I love is block printing. The traditional block print fabric process takes a block of wood, carves a unique pattern into it, and then uses it as a stamp to print fabric. This ancient technique creates local jobs in Bagru and Sanganer, is completely free of electricity, and uses less water than any other printing method (including digital printing). Our Bagru printing partners go one step further and only use organic cotton fabrics and natural dyes from vegetables as well as low-impact dyes. today I am going to give you a What's Behind The Seams insider look into the making of famous Bagru prints.

History Of Hand Block Printing In India

From China to India

According to many historians, printing first began in China about 4,500 years ago.

But, there is alot of misinformation that we need to sort through with India's printing history. That story (woven by many Western bloggers who have not done the research) goes, that through trade routes, printing techniques made their way to India only as recently as 400 years ago thanks to trade routes.

But this is very wrong. India was printing long, long, before they started trading with Europe.

Block printing technique originated in Gujarat and dates back to the 12th century. From Gujarat, the technique spread to Rajasthan. Like accents within the same language (think southern "yall" or New York - "I'm walkin' here!"), each geographical area of India has its own unique process and distinct aesthetic. China's designs and imports only ignited an industry that already had a rich history.

International Influence And Demand

At the same time there were so many international influences in India thanks to the trade routes and local artisans began to draw from these new inspirations. This influence coupled with India's superior understanding of dyes and printing (especially with natural plant dyes), made them a world leader in block printing.

The new fabrics were coveted by the Mughal Maharashtra that ruled at the time as well as the nobility of Europe. Many of the floral print fabrics we see in museums and that are still reproduced in Jaipur today, were influenced by European styles during this time period.

But, with the industrial revolution and invention of mass production, the time-consuming and expensive fabrics fell out of vogue. For years the cottage industry of hand block printing hung on by a thread (literally), with one of the last popular items being Bagru print sarees for more wealthy Indian ladies.

Today the Chippa caste, especially the Chippa families in Bagru printing villages, help to keep the craft alive.

The next generation of Bagru printers at Block Print House.

Hand Printed Village Influence

This is just a quick teaser. I am working on a post about the different influences and characteristics of block print design throughout India. But here is something I find really cool about India's block prints...

What's interesting about block print fabrics is that based on the design and style, you can often tell what region the fabric was made in.

Gujarat is known for bold geometric patterns, Sanganer for calicos. And, Bagru prints (where our block prints come from) are known for a special hand block printed fabric technique called Dabu and the use of indigo dye. Dabu printing is one of my favorite printing techniques and you can learn more about it here.

It’s incredible to see how many unique cultural interpretations can be created using the same ancient process.

Today pareo Jaipur prints and print cotton scarves are two of the most popular block print items for export. If you don't know, pareos are basically like sarongs.

How To Block Print

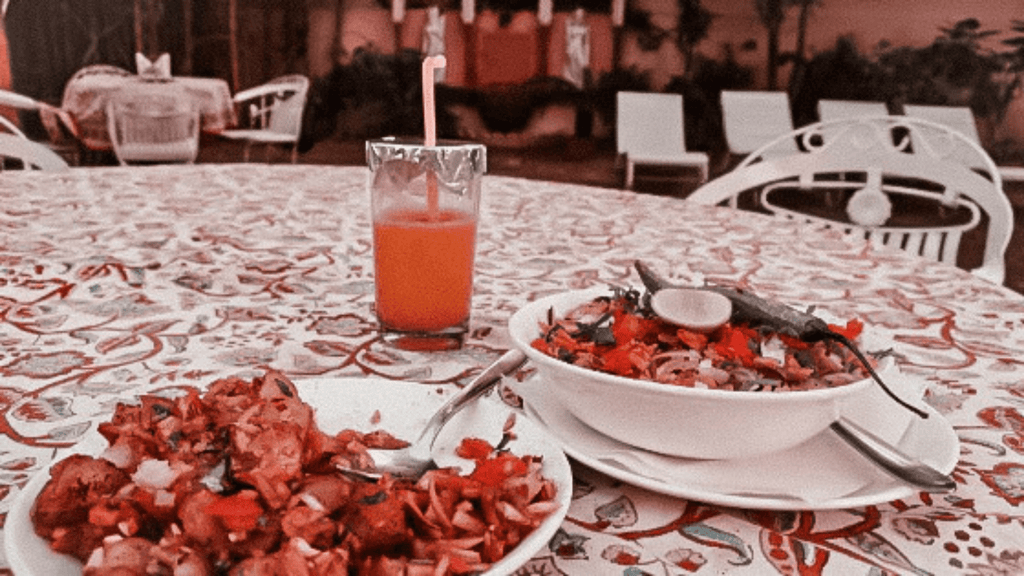

Block prints are EVERYWHERE in Jaipur, even at the breakfast table. For breakfast this morning - aloo chaat, poha, and fresh orange juice

Before You Even Start Printing You Need To Make the Block

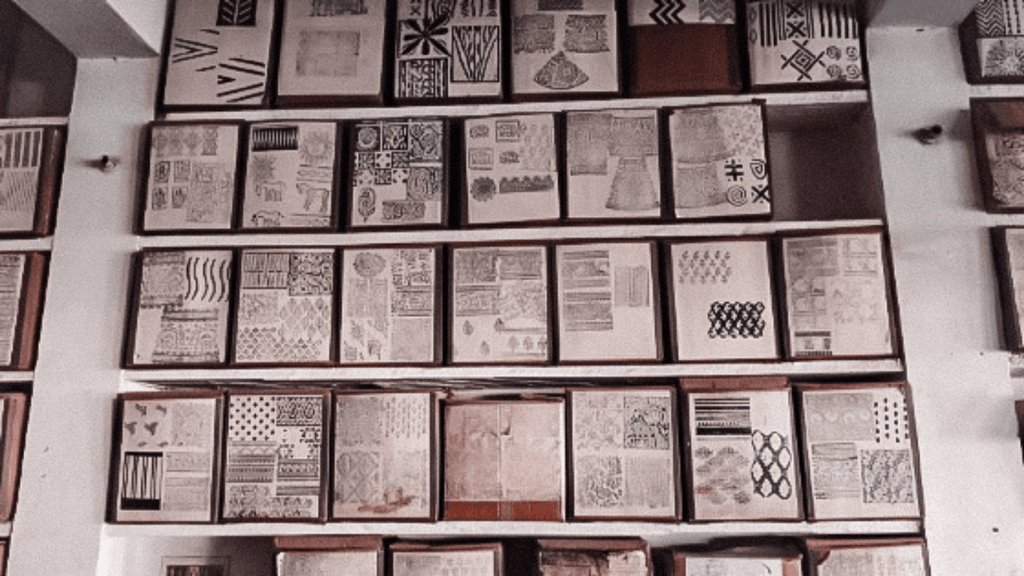

Not feeling creative? That's ok. Try mixing and matching from a print houses block library.

The first step is designing. Each color in a print get's its own block. So a three-color print would have 3 separate blocks. Blocks generally measure under 12" x 12". And prints generally should not have more than about 5 colors. Anything bigger or more complex than that will need to be a screen print. And for screening, I recommend taking a trip to another nearby village, Sanganer.

Screen printing in Saganeer - but more on that another time...

Carve

Artisans carving blocks in the village of Bagru.

The carving process is where the designs are transferred onto a wooden block.

Block carving starts with a block of wood and a paper pattern. The block is painted white for contrast, and the paper pattern is attached to the block.

Workers transfer the design onto the block by making tiny little dots on the lines of the pattern. Artisans then remove the paper and use the dots as a guide for carving by hand.

Finished blocks.

Fabric Prep

Alittle bit of a mild detergent, and LOTS or heat to desize fabrics

One of the most important steps, that most people don't know about, when printing fabric is desizing.

When fabric is knit or woven a coating, aka sizing, covers the yarns to help keep them strong and prevent damage. Sizing is usually made of a petroleum base, but, often in India, something as simple as corn starch does the trick.

Before a piece of fabric can go into dying or printing the sizing needs to be removed, this is the process of scouring. Usually, a mild detergent and a lot of boiling are all that is necessary to remove the sizing. No crazy chemicals.

This step is super important. If the yarns in fabric are coated, the dyes and prints will not be able to penetrate the fibers properly and the result will be a print that washes away or is inconsistent in color.

Add Mortant

Next in the processing is adding some mordant. Mordant helps the ink from printing stay on the fabric and not wash away. You can think or mordants as the glue that holds the natural color on.

Different fabric contents and different dyes need different types of mordants. But, generally for cotton fabrics are artisans use tannins.

Prep The Color

Ladies preparing color for block printing.

This is a fun step. It's where we create custom colors. Different base colors, think red and yellow make orange, blue and red make purple, etc, are mixed together to create the perfect custom color.

I personally prefer to use natural colors from plants. But, it is important to remember that natural plant color dyes have their limitations. Natural dyes have less saturation and less possible colors than chemical dyes.

It's Almost Time To Start Printing - Plan Ahead

I am the kind of person that leaps before they look. I get so excited and am so eager to try new things and create, I usually just go for it. And, this is almost always a mistake. The best advice I can give for block printing is to plan ahead. Measure and map out where each block is going to hit the fabric before starting.

Time To Print

I can not tell you how many times I start printing to figure out halfway through that I would not have enough room to print my entire concept, or my design was totally off-center. My dad always says measure twice and cut once, and this advice definitely transfers to block printing.

Dip The Block

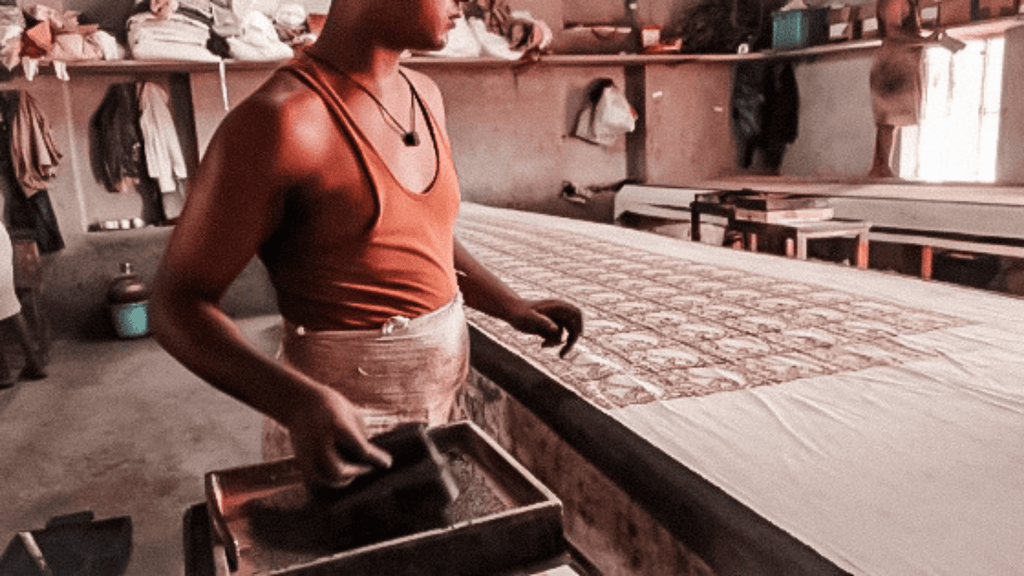

An artisan at work, doing what he does best - Bagru printing

You want to get just the right amount of print paste on your block.

There is a log of printing technique for this. I tend to have a very heavy hand, and often get too much ink on my block. The goal is to lightly tap the block into the print paste.

Get Ready To Print

More technique (read, skill) here.

Line up the block over the fabric. Be really careful, because once the block goes down on the fabric there are no do-overs. But, when the block is exactly where it needs to be, drop it down onto the fabric.

Stamp It

The block gets a quick pound with the fist. In my case I am weak, so I have to give it a few bangs. My friend Arielle, over at four rabbit uses a mallet to tap the blocks to prevent bruising on her fists.

Smart idea.

Repeat

Try mixing and matching different colors and blocks and keep on printing until the entire fabric is done.

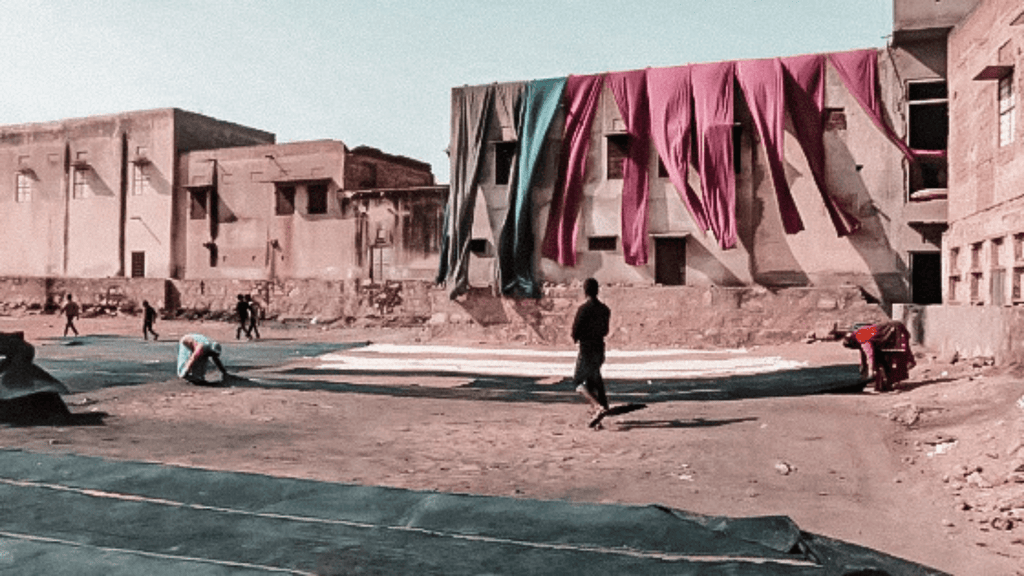

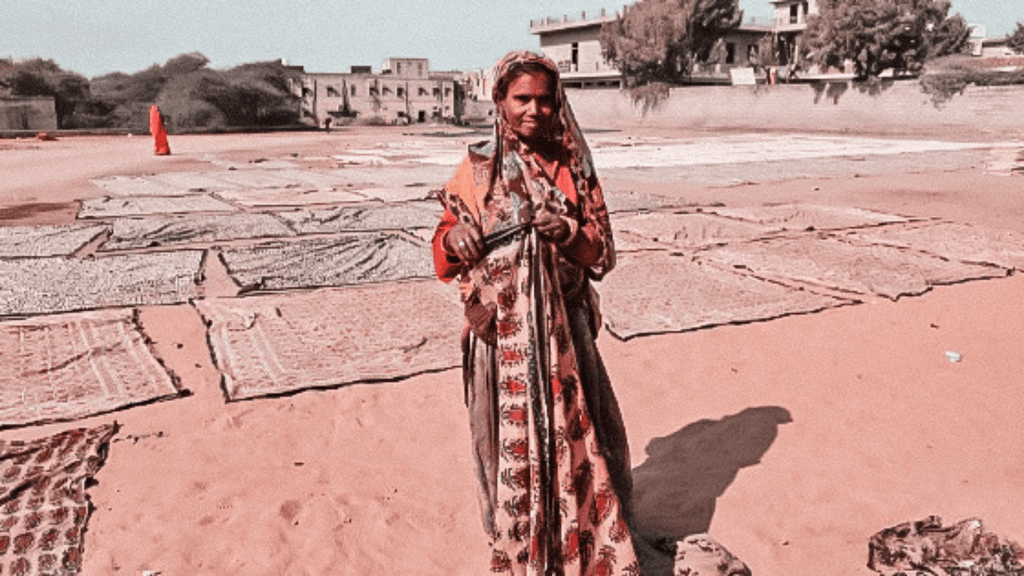

Dry

Once the printing is done, the fabric dries naturally in the sun. The heat from the sun also helps "cook" in the color. But, the fabric is not ready yet.

Wash + Steam or Dye

The finished fabric needs and alum washing, to help keep the prints colorfast during the home laundering process. After the wash, it is again drys in the sun.

Then the fabrics are usually steamed (depending on the dyes and fibers) to help lock in the color even more. This process also usually changes the print color slightly creating a more vibrant hue.

The result is a beautiful, handcrafted Bagru hand block print fabric that is made without the use of electricity, is toxin-free, and uses minimal water!

Or, the fabric can get one extra process, an overdye. This means that a dye color is chosen to dye over the print, this way the background of the fabric is another color other than white.

Because Bagru is historically known for indigo, I usually like to dip my fabrics in an underground indigo vat. Some of the indigo wells in the area are over 100 years old!

Block Prints In Fashion

Don't sweat the small stuff, imperfections are part of the process. Remember, these are people. Not machines. And, people are not perfect. There are going to be little inconsistencies in the print. And, the colors are not going to line up perfectly. That is the beauty of block prints.

One of the biggest challenges for small brands with block print products is that often boutiques and retailers don't understand how variances are part of the design, not defects. Luckily, as traditional Indian crafts become more and more popular on a global scale, more people are understanding that perfection is not the goal. (Maybe things like a living wage, and safe work space are…)

Please Don't Appropriate

Come up with your own designs.

Please don't come to Jaipur and steal from the local people. I think part of what makes artisan crafts so appealing to Westerners is the colors and chaos. Like India in general, traditional block prints are over the top.

Coming from places like NY, LA, and London, where prints and colors are a little more muted, it's easy to understand why people fall in love and want to emulate the striking designs.

But, just don't.

Use India's unapologitic use of colors on colors, prints on prints, and mentality of more is always better to amplify your own designs. Again, do not steal from the local Bagru print motifs.

If you need a lesson on stealing local cultures designs, here is an article about Carolina Herrera.

Take A Class And Learn From An Artisan

Try a local Bagru block printing workshop.

A few years ago, during my first virtue + vice 10-Day Sustainable Fashion Tour, the group spent a day in Bagru and go to learn all about the history of the village, and try their hand at Bagru block printing themselves.

I wish everyone could try block printing for themselves. It's really difficult, and I feel like everyone would have so much more respect for their clothing if they were able to experience how labor-intensive it is to make.

Also, it is just really cool to see where the West Elm or Anthropology "tribal" bedding or pillowcase from your house actually came from.

And, As Always, Try To Shop From Artisans Directly

Is block printing ethical?

Yes and No.

It creates jobs. Lots of jobs. So many hands will touch a piece of fabric through all of these steps. And, because the practice is time-consuming and labor-intensive, a lot of people are necessary for the production process in comparison to machine printing.

In India jobs are scarce. There simply are not enough jobs for the entire population.

Hey, entrepreneurs out there… thinking about starting an ethical and sustainable clothing line? Please remember this - the most impactful thing you can do while working in India is to help create a job. A job that provides a living wage.

India does not need your donations, they need consistent work.

But, while the Bagru print fabric wholesale market is creating more much-needed jobs, there is also a darker side.

Many Indians Cannot Afford Their Own Work

The people who are making these block print fabrics often make so little that they can not afford their own work. In the local markets around Jaipur, there are cheaper knockoffs that are not as high quality as the fabrics made for export. This is what locals buy and wear. They don't get the same things like me and you.

This same sentiment was echoed during my interviews with khadi fabric weavers. While speaking to the artisans they would ask me who the people were that wore the fabrics they made, because, aside from the occasional foreigners visiting from the US, Europe, or Australia, they never actually saw people wearing the fabrics in their own communities because they were so expensive ($15/meter or more).

It's heartbreaking listening to them. Artisans spend so much time creating beautiful textiles, sadly most of which will end up in landfills. And, they can't even wear their own creations.

That is why paying attention to workers' wages is so important.

What Do You Think?

Is that sustainable? Is that ethical? I am not going to tell you what is right and wrong. The world of sustainable and ethical fashion is full of grey areas and blurred lines. But, it is something to think about the next time you are getting a sales pitch about how "ethical" a company is.

A Man's Job

Traditionally block printing has been a man's job. But, India is slowly changing and women are gaining more and more rights and working in new industries every day. If you want more info on women in block printing, check out Symbology who has been doing great work in the Jaipur region with women for almost a decade.

You never know what you are going to find in a block print house in Bagru! On this day a pack of puppies took over!

Questions Or Comments?

Let me hear them below.

Leave a comment